July 9, 2018

The average American spends 93% of their life indoors. For a school aged child, that is spent largely at school. According to National Center for Education Statistics (NCES), there are almost 99,000 public K-12 schools in America and the average public-school building in the U.S. is 42 years old. Our students are spending their days in aging facilities with physical deficiencies that may be prohibiting their learning capabilities.

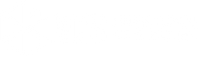

Those in school planning and design have taken this as an opportunity to enhance academic outcomes by created learning environments that live up to the standards many district’s demand of their students’ academics. Clean, quiet, safe, comfortable, and healthy environments are components essential to successful teaching and learning. Rebuilding and updating outdated facilities is essential to the health of our education system. Architects, engineers and owners alike are taking a student-centric approach to modern school building. They are combating some of the biggest health issues in schools with effective HVAC design and mechanics which include poor indoor air quality, temperature and humidity, and ventilation.

HVAC-Related Health Issues in Educational Facilities

Poor Indoor Air Quality

Studies show that 15,000 schools across the US suffer from poor Indoor Air Quality (IAQ), affecting more than eight million children or one in five children in America’s schools. Poor Indoor Air Quality, or breathable air with dust, germs, bacteria and mold can cause Sick Building Syndrome. Sick Building Syndrome is associated with symptoms such as irritated eyes, nose and throat, upper respiratory infections, nausea, dizziness, headaches and fatigue, or sleepiness. The issue is simple. Sick students and teachers don’t perform as well as healthy ones.

Poor IAQ leads to increased student absenteeism. A study conducted by Smedje and Norback and Rosen and Richardson found a positive relationship between airborne bacteria and mold to asthma in children, which, in turn, increased absentee rates. Further, the American Lung Association (ALA) found that American children miss more than ten million school days each year because of asthma exacerbated by poor IAQ.

The Occupational Safety and Health Administration (OSHA) and the National Institute of Occupational Safety and Health (NIOSH) call for fifteen and twenty cubic feet of air per minute per person to deliver more fresh air and dilute and remove contaminants. Avoiding the build up of dust, germs, bacteria and mold in the air is essential to occupant health.

Temperature and Humidity

Temperature and Humidity affect levels of bacteria and mold in a space, which directly impact your facility’s indoor air quality. Additionally, studies prove that students perform mental tasks best in rooms kept at moderate humidity levels (40-70%) and temperatures in the range of 68-74 degrees.

Thermal temperature affects occupant’s concentration, memory and learning ability. It also affects teachers’ ability to teach and overall attitude towards their work. According to a study conducted by Lowe in 1990, the winners of the state teachers of the year awards, the best teachers in the US, emphasize their ability to individually control classroom temperature.

Ventilation

The purpose of ventilating classrooms and school buildings, at a minimum, is to remove or dilute contaminants that build up inside. Contaminants come from breathing, skin, clothes, perfumes, shampoos, deodorants, building materials and cleaning products, pathogens, and from a host of other agents that can be harmful in certain concentrations.

Children breathe a greater volume of air than the average fully-grown adult based on body weight, making proper ventilation essential in schools. Most educational facilities have much less floor space per person than found in most office buildings. The problem lies in the high cost of conditioning and ventilating air to comfortable temperatures before it starts circulating. Due to budget restraints, neglect, poor maintenance or some combination of these factors, many designers and operators are unwittingly creating ineffective learning environments due to inadequate ventilation.

What You Can Do to Improve Learning Environment Health

Watch for Symptoms

Building occupants often associate health symptoms they experience with poor environments. However, determining if health symptoms relate to IAQ problems can be difficult. Acute, or short-term, symptoms are typically similar to cold, allergy and flu. The symptoms below may be an indication of underlying IAQ issues:

- Chest tightness or shortness of breath

- Chills

- Cough

- Diagnosed infection or clusters of serious health problems

- Dizziness

- Eye, nose and throat problems (congestion, swelling, itching or irritation)

- Fatigue, drowsiness, dizziness or lethargy

- Fever

- Headache

- Nausea

- Shortness of breath

- Sinus congestion

- Skin irritation

- Sneezing

Take Action to Ensure that Schools Are Well-Maintained

As school budgets tighten, school boards and administration often consider the maintenance budget as an expense to be cut without affecting the core academic program needs. However, a good maintenance program is integral to ensuring that school health and academic programs achieve their fullest potential. An effective maintenance program can reduce both energy costs and long-term repair costs.

Sources:

The post The Importance of HVAC to the K-12 Learning Environment appeared first on Building Controls and Services, Inc..